The Q.Grip Project

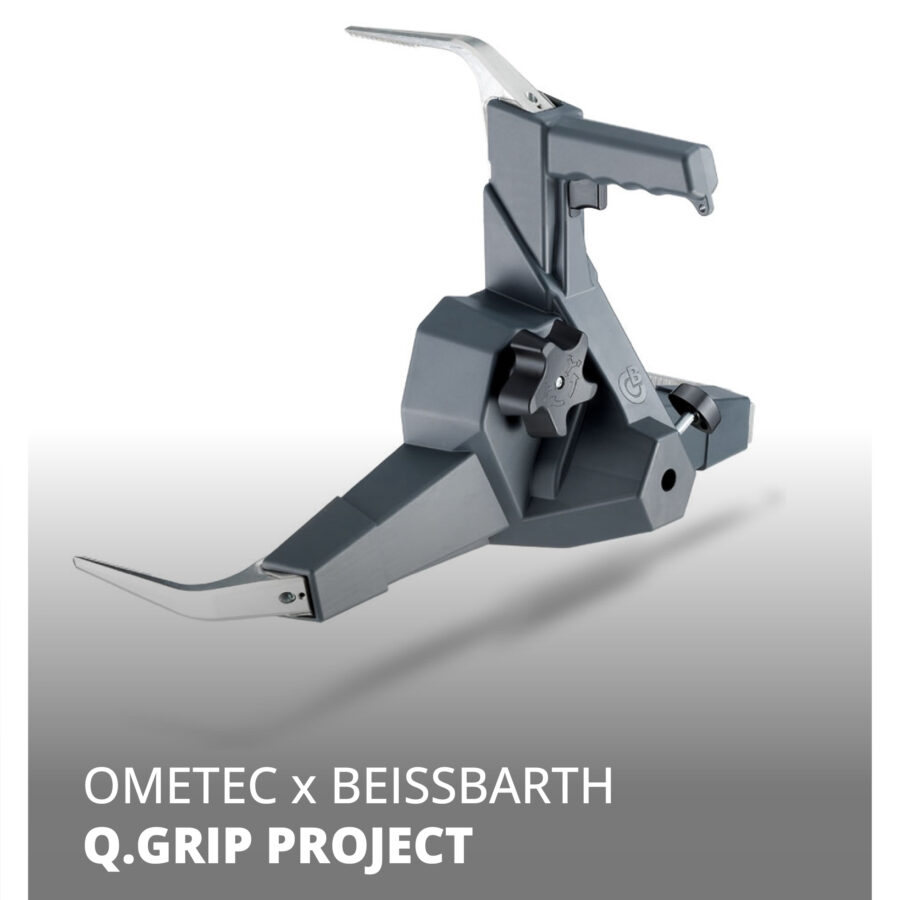

The Q.Grip is a tire anchoring tool for vehicle alignment and convergence systems.

Innovative, fast, and easy to use, it can be applied to wheels of different sizes in just a few seconds. Thanks to its tri-arm design, it ensures a secure grip for precise results, without slipping or damaging the rims.

The Q.Grip project was initiated at the request of Beissbarth ATS GmbH in January 2021.

The first step involved the creation of a mold for the product’s supporting shell. From this initial collaboration, a broader partnership developed, leading to the design and production of seven additional molds, all related to the Q Line project.

The partnership was further consolidated when Beissbarth asked Ometec to conduct a feasibility study focused on assembling the internal components necessary to obtain the final product.

We first carried out a technical analysis to identify all possible operational phases, related methods, timelines, and potential weak points of what would later become the assembly process.

Ometec presented a preliminary study on the assembly process and positioned itself as a partner for product development, production process implementation and optimization, and supply chain management.

After manufacturing the molds needed for the plastic components, in April 2021 Ometec was assigned to produce the Q.Grip and to manage the project in all aspects: raw material sourcing, commercial components, CNC-machined metal parts, thermoplastic component molding, and final assembly.

Mass production began with the drafting of detailed operating instructions defined by Ometec, approved by the client, and implemented alongside staff training through printed documentation, photographic material, and multimedia resources.

Particular attention was given to packaging features with the co-design of a “bi-pack” container with anti-collision internal compartments. The outer shell, internal dividers, and paper adhesive tape make it reusable and fully recyclable.

Ometec’s commitment to the project continued when the client requested a study on process and product optimization aimed at cost reduction. The company responded with a series of technical and commercial solutions.

The most impactful solution was to replace certain internal metal components with plastic ones, reducing procurement, processing, and management costs.

Ometec Engineering & Molds Division supported Beissbarth in the required design changes, designing and producing new molds for thermoplastic materials.

All metal parts previously produced via CNC were replaced, after validation, with plastic components made from high-performance thermoplastic resins and with significantly shorter processing cycles.

The Product and the Process

The complex assembly stages required a high level of specialization from the operators, who actively contributed to the project’s launch, development, and consolidation.

The assembly stations, initially two, doubled during the first year of operations. They are equipped with electric and pneumatic screwdriving systems, assembly jigs, workbench tools, and measuring and inspection instruments.

Accuracy, precision, and strict adherence to each assembly procedure are supported by video files always available for viewing directly at the line.

Operators carry out their production tasks and digitally record quantity and quality through a self-inspection system.

A dedicated database collects all the information needed to achieve and maintain the required quality standards. Every aspect, issue, deviation, or noteworthy event is recorded as potentially useful for continuous improvement and for managing possible internal, external, or after-sales claims.

Customer Service

Complementing Ometec’s comprehensive support is the management of recovery and reconditioning of used, worn, or damaged parts.

In line with sustainability, non-functional Q.Grips return to Ometec to be inspected, refurbished, and reconditioned, then returned to the client in like-new condition.

This activity, far from secondary in importance, also allows the monitoring of the effectiveness of improvements introduced over the years and the identification of potential new areas for improvement.